Reposted from BoshartU. Click here for original article.

You may know them as a wall hydrant, lawn faucet, non-freeze wall hydrant, non-freeze lawn faucet, frost proof, non-freeze sillcock or even frost-proof wall hydrants. Don’t let that confuse you though, they are the same thing. We will be referring to them as wall hydrants in this blog.

In this blog we are going to look at what a wall hydrant is, how they work, and the importance of preventing back flow. Let’s dive in shall we!

What is a wall hydrant?

A wall hydrant is a valve that provides the convenience of water outside your house while requiring little winterizing. Ideally used where freezing is possible, wall hydrants protect against damage. The shut off occurs inside the house where there is no chance of freezing. They provide back flow protection in commercial and residential applications.

How does a wall hydrant work?

The handle is turned outside but the valve that controls the flow of water is on the other side of the wall. This is done though a stem that opens and closes a valve inside the house. In the closed position, a bibb washer is forced against the faucet seat stopping the water.

To turn the valve on simply turn the handle and the stem will open the bibb washer allowing water to flow freely though the valve. To turn it off, simply turn the handle the other way and the stem will press the bibb washer against the seat preventing more water from flowing though the valve. Water that is in the valve will drain out leaving it empty.

Wall Hydrants need to be installed at a three to five degree incline where the inlet is higher than the outlet. This allows the valve to drain ensuring there is no water left in the valve to freeze. To help with this, a plastic wedge can be placed securely between the wall and the wall hydrant flange.

How is back flow prevented?

When there is unequal pressures within the water system, a vacuum can be created where water flows backwards back into the house. This is called back flow or back siphonage. If the water that the end of the hose is submerged in is toxic or contaminated, that water would flow back into the system. But good news, this can be easily prevented.

If you already have a hose installed make sure the end of the hose is not submerged in the liquid. Having an air gap between the hose and water will always prevent back siphonage.

Wall Hydrants can take this one step farther by including a check valve and vacuum breaker. The check valve is at the end of the stem and closes when water tries to flow back into the system. A vacuum breaker allows air to enter the valve eliminating a vacuum within the system and ensuring the valve drains completely.

Before removing a faulty wall hydrant I would recommend doing a bit of research about it. Some wall hydrants can easily be repaired instead of replaced. If it needs to be replaced think about installing one that can be repaired in the future. It could just be a worn out piece that needs to be replaced.

Whether you know it as a wall hydrant or a non-freeze lawn faucet, these valves are excellent for providing water outside. With the built in back flow protection and little winterizing required these sure are great valves!

Reposted from BoshartU. Click here for original article.

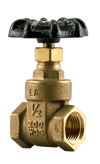

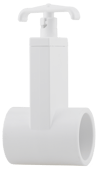

Gate valves and knife valves are linear motion valves, which include a flat closure element called a gate. The gate inside the valve slides up and down by turning a

Gate valves and knife valves are linear motion valves, which include a flat closure element called a gate. The gate inside the valve slides up and down by turning a  hand wheel counterclockwise to open and clockwise to close. For knife valves, you simply slide the gate by pushing or pulling the handle. Both valves move the gate into the flow stream to stop the flow of fluid completely. To explore what the markings found on gate and ball valves mean, check out our blog post,

hand wheel counterclockwise to open and clockwise to close. For knife valves, you simply slide the gate by pushing or pulling the handle. Both valves move the gate into the flow stream to stop the flow of fluid completely. To explore what the markings found on gate and ball valves mean, check out our blog post, .png?width=425&name=My%20Post(268).png)

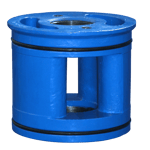

-1.png?width=150&name=WS40%20(top)-1.png) name from the grey appearance that the fractures of the material give off. Grey cast iron is the most commonly used cast iron and is the most widely used cast material due to the weight. Grey cast iron’s strength is comparable to low or medium carbon steel, but it has less tensile strength and shock resistance compared to steel. Common items made from grey cast iron are well caps and well seals.

name from the grey appearance that the fractures of the material give off. Grey cast iron is the most commonly used cast iron and is the most widely used cast material due to the weight. Grey cast iron’s strength is comparable to low or medium carbon steel, but it has less tensile strength and shock resistance compared to steel. Common items made from grey cast iron are well caps and well seals. Cast Iron

Cast Iron Malleable Cast Iron

Malleable Cast Iron

Standard PTFE tape is mainly used for water system connections, either potable or non-potable as they are corrosion and acid resistant. Applications where the standard PTFE tape works best is in high pressure lines and used best with most chemicals.

Standard PTFE tape is mainly used for water system connections, either potable or non-potable as they are corrosion and acid resistant. Applications where the standard PTFE tape works best is in high pressure lines and used best with most chemicals.

Gray Stainless Steel

Gray Stainless Steel