Reposted from BoshartU. Click Here for original article

Nylon vs Poly vs PVC… which one do you need? The choice seems simple, just pick one. But it actually is a bit more complicated than that. Each material has it’s strengths and it’s weaknesses. They have noticeable differences; Nylon is a natural colour, Poly is a light grey and PVC is a dark grey, but what about the non obvious differences?

In this blog, we will go over the pros and cons of each material and what applications each one is the most suitable for. This will make it easy for you when you next require a plastic fittings. Let’s take a look.

Nylon

Strengths

NE-15

Nylon is the toughest material between Nylon, Poly and PVC. Nylon is exceptional for water well and underground applications. It is extremely durable which makes it good for barns, livestock and watering systems. Nylon can handle the largest abuse of stretching and twisting.

Weaknesses

Nylon is not good for exposure to sunlight. Ultraviolet rays can cause nylon fittings to become extremely brittle and fail. There is also a very small number of chemicals that are good to be used with nylon fittings.

Poly (Polyethylene)

PPRC-1512Strengths

Poly is the most economical of the three materials and it has really good chemical resistance. It is extremely popular in the pool and spa market. There are a handful of chemicals that can be used with poly fittings that cannot be used with PVC fittings.

Weaknesses

Poly is the least durable of the three materials and there are less items available in reducing fittings.

PVC (Polyvinyl Chloride)

Strengths

PVC has the widest range of fittings. It is most popular in irrigation applications since it is not affected by ultraviolet rays. It has great chemical resistance and there are some chemicals that PVC can handle that Poly cannot. It is a very tough material which is why it is used in irrigation systems where lines are not below the frost level.PVCT-20

Weaknesses

PVC has no noteworthy weaknesses like nylon or poly, but it is normally more expensive than poly fittings. Depending on the application you require an insert fitting for, PVC may be an over kill. Nylon and Poly could be a better fit for a certain application so ensure you do your research on what you require the fitting to handle before making the decision. In doing that you could save yourself some money.

Applications

In irrigation systems, all lines need to be blown out in the winter to prevent damage from freezing. It is almost impossible to remove 100% of the water from the pipes, so that means that some water will still be in the line after they are blown out. PVC fittings are best suited for this application since the expansion from the ice will be forced length wise in the pipe instead of expanding the diameter of the fitting. This ensures the pipe and gear clamps will maintain a strong seal.

Nylon may be a tough material but in this particular case, nylon fittings will stretch in diameter. If this stretching occurs, it could loosen the clamp, and since nylon has a size memory, it will return to it’s original size which will ultimately cause a leaky connection.

As you can see above, each material has their notable strengths and weaknesses. Depending on the application you require the fittings for, that will determine which material is the best option. Keeping these pros and cons in your back pocket will help to guarantee you pick the correct material for your specific application.

Reposted from BoshartU. Click Here for original article

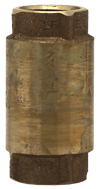

The placement and number of check valves required for a system is based on the depth of the pump setting in the well. Installation of 200 feet or less require one check valve on the pump discharge and one on the surface of the well. Settings 200 feet or deeper may require multiple check valves. Some thing to consider during installation is the weight of piping, water and submersible pump, head loss of the valves, friction loss of the piping, velocity of water and water hammer. For more on check valves and what their job is, check out

The placement and number of check valves required for a system is based on the depth of the pump setting in the well. Installation of 200 feet or less require one check valve on the pump discharge and one on the surface of the well. Settings 200 feet or deeper may require multiple check valves. Some thing to consider during installation is the weight of piping, water and submersible pump, head loss of the valves, friction loss of the piping, velocity of water and water hammer. For more on check valves and what their job is, check out  into poly riser pipe. A second adapter can be threaded into the pitless adapter at the well head and then connects to the poly riser pipe. The lug with a hole, or the rope eye, provides a simple means to securely fasten the safety rope or cable or to secure the submersible pump to the well head in case of a pipe failure. Available in bronze and stainless.

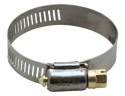

into poly riser pipe. A second adapter can be threaded into the pitless adapter at the well head and then connects to the poly riser pipe. The lug with a hole, or the rope eye, provides a simple means to securely fasten the safety rope or cable or to secure the submersible pump to the well head in case of a pipe failure. Available in bronze and stainless. Hose clamps are designed for sealing poly pipe to barbed insert fittings, making a positive watertight seal and pull-off proof connection. Using an all 300 grade stainless steel clamp ensures the clamp will last the life of the system for water well installations or where maximum corrosion resistance is required. For a more in depth look at clamps, check out

Hose clamps are designed for sealing poly pipe to barbed insert fittings, making a positive watertight seal and pull-off proof connection. Using an all 300 grade stainless steel clamp ensures the clamp will last the life of the system for water well installations or where maximum corrosion resistance is required. For a more in depth look at clamps, check out  and the leads on the pump motor. The connection is made by cutting the cables in a staggered position to decrease the outer cable diameter. This is an important step in order to reduce the risk of damaging the splice due to abrasion when the pump is lowered into the well.

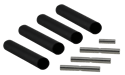

and the leads on the pump motor. The connection is made by cutting the cables in a staggered position to decrease the outer cable diameter. This is an important step in order to reduce the risk of damaging the splice due to abrasion when the pump is lowered into the well. Torque arrestors are specifically designed to keep the submersible pump centred and to prevent any twisting in the well casing. Torque arrestors also protect the pump cable and are typically installed directly above the pump on the riser pipe. They can be installed on 1″ and 1- 1/4″ riser pipe.

Torque arrestors are specifically designed to keep the submersible pump centred and to prevent any twisting in the well casing. Torque arrestors also protect the pump cable and are typically installed directly above the pump on the riser pipe. They can be installed on 1″ and 1- 1/4″ riser pipe. the well head. The main function is to prevent the pipes from separating which could result in the pump being lost at the bottom of the well. Safety rope can also provide a backup to enable the installer to pull the pump from the well if the riser pipe fails. Every pump should have a safety rope secured to it before hanging it in the well.

the well head. The main function is to prevent the pipes from separating which could result in the pump being lost at the bottom of the well. Safety rope can also provide a backup to enable the installer to pull the pump from the well if the riser pipe fails. Every pump should have a safety rope secured to it before hanging it in the well. Submersible pump cable is used to supply the power to the submersible pumps. Typical pumps used in a submersible pump installation are either a two or three wire pump. The two wire pumps have the starting capacitor built into the submersible motor whereas the three wire pumps do not have the capacitor built into the motor, they require a control box which is normally found in the pump house at the well head. For more on pump cable, check out our post

Submersible pump cable is used to supply the power to the submersible pumps. Typical pumps used in a submersible pump installation are either a two or three wire pump. The two wire pumps have the starting capacitor built into the submersible motor whereas the three wire pumps do not have the capacitor built into the motor, they require a control box which is normally found in the pump house at the well head. For more on pump cable, check out our post  cable is not properly protected, the insulation on the wires feeding the pump can get worn out due to rubbing against the inside of the well casing. Every time the pump stops or starts, the whole installation moves in response. After years of this action, the wire insulation will thin resulting in a short circuit.

cable is not properly protected, the insulation on the wires feeding the pump can get worn out due to rubbing against the inside of the well casing. Every time the pump stops or starts, the whole installation moves in response. After years of this action, the wire insulation will thin resulting in a short circuit. Cable ties are used to effectively secure the riser pipe to the pump cable between the cable guards. Some codes require the cable ties to be fastened to the riser pipe at intervals of no greater than 10 feet apart.

Cable ties are used to effectively secure the riser pipe to the pump cable between the cable guards. Some codes require the cable ties to be fastened to the riser pipe at intervals of no greater than 10 feet apart. the underground discharge pipe. The discharge pipe transfers the water to your home below frost level. The threaded tapping on the pitless elbow allows the adapter to be connected to the lift out pipe to lift riser pipe and the pump assembly up out of the well. To look at slide pitless adapters a little closer, check out

the underground discharge pipe. The discharge pipe transfers the water to your home below frost level. The threaded tapping on the pitless elbow allows the adapter to be connected to the lift out pipe to lift riser pipe and the pump assembly up out of the well. To look at slide pitless adapters a little closer, check out  of attaching the safety rope securely to the well casing at the well head, rather than fastening the rope directly to the other internal components. The rope hanger can easily be removed and set to the side when the pump is pulled from the well if the well needs to be replaced or serviced. For more on safety rope and rope hangers, check out

of attaching the safety rope securely to the well casing at the well head, rather than fastening the rope directly to the other internal components. The rope hanger can easily be removed and set to the side when the pump is pulled from the well if the well needs to be replaced or serviced. For more on safety rope and rope hangers, check out  There are a variety of types of well caps but they all provide a watertight seal to protect the well from any contamination. To learn more about the different types of well caps and the different materials they come in,

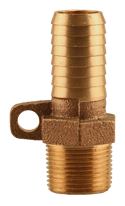

There are a variety of types of well caps but they all provide a watertight seal to protect the well from any contamination. To learn more about the different types of well caps and the different materials they come in,  An insert adapter has one end that is insert and the other end is MPT (Male Pipe Thread). When hanging a pump on the poly riser pipe, it is recommended to use an extra long insert adapter for added protection of the pump from accidentally pulling out of the insert. You can also double or triple clamp the insert fittings to ensure the connection will never slip. For a closer look at bronze insert fittings, check out our blog,

An insert adapter has one end that is insert and the other end is MPT (Male Pipe Thread). When hanging a pump on the poly riser pipe, it is recommended to use an extra long insert adapter for added protection of the pump from accidentally pulling out of the insert. You can also double or triple clamp the insert fittings to ensure the connection will never slip. For a closer look at bronze insert fittings, check out our blog,  low producing wells. Flow controls allow the aquifer to sustain a static water level in the well and not allow it to fall below the submersible pump to prevent the pump from running dry due to over pumping the well. You can install a flow control anywhere between the submersible pump and the tank tee at the pressure tank connection, but they can be used in other locations as well. To dive into flow controls a little deeper, check out our blog,

low producing wells. Flow controls allow the aquifer to sustain a static water level in the well and not allow it to fall below the submersible pump to prevent the pump from running dry due to over pumping the well. You can install a flow control anywhere between the submersible pump and the tank tee at the pressure tank connection, but they can be used in other locations as well. To dive into flow controls a little deeper, check out our blog, .png?width=150&name=07ST-13SF-2U%20(top).png) Tank tees are multi-port fittings designed specifically to connect a tank to the water system. Having the multi-port feature allows one fitting to do the job as eight or more pipe fittings. The connection on the legs goes to the tank and one of the lateral connections goes to the pump. Another connection goes to the plumbing system. Water from the pump can then go either into the tank or directly into the plumbing.

Tank tees are multi-port fittings designed specifically to connect a tank to the water system. Having the multi-port feature allows one fitting to do the job as eight or more pipe fittings. The connection on the legs goes to the tank and one of the lateral connections goes to the pump. Another connection goes to the plumbing system. Water from the pump can then go either into the tank or directly into the plumbing. back and forth reacting to the water system pressure. Pressure switches come in standard, medium and heavy-duty models that handle a wide variety of electrical and pressure ratings. For more information on pressure switches, check out our blog,

back and forth reacting to the water system pressure. Pressure switches come in standard, medium and heavy-duty models that handle a wide variety of electrical and pressure ratings. For more information on pressure switches, check out our blog,  A pressure gauge allows you to easily monitor what the pressure system is doing and to confirm what the cut-in and cut-out pressure settings of the switch are. They are installed in one of the two upward facing accessory ports on the tank tee head. Glycerine filled gauges can reduce any motion that could occur on the indicator pointer due to system vibrations. Check out our blog,

A pressure gauge allows you to easily monitor what the pressure system is doing and to confirm what the cut-in and cut-out pressure settings of the switch are. They are installed in one of the two upward facing accessory ports on the tank tee head. Glycerine filled gauges can reduce any motion that could occur on the indicator pointer due to system vibrations. Check out our blog,  were to fail allowing the system to continue building pressure beyond the pre-set pressure of the switch. Excessive pressure could result in major failure of the plumbing pipe and the plumbing components, potentially resulting in water damage. Take a closer look at

were to fail allowing the system to continue building pressure beyond the pre-set pressure of the switch. Excessive pressure could result in major failure of the plumbing pipe and the plumbing components, potentially resulting in water damage. Take a closer look at .png?width=150&name=0852-07NL%20(cert).png) A drain valve is installed in the second outward facing accessory port. Drain valves provide a means to take water samples, acquire water from systems and allows access to drain the tank and water system if the pressure tank needs to be replaced. Drain valves are also known as sediment faucets or boiler drain valves.

A drain valve is installed in the second outward facing accessory port. Drain valves provide a means to take water samples, acquire water from systems and allows access to drain the tank and water system if the pressure tank needs to be replaced. Drain valves are also known as sediment faucets or boiler drain valves. isolation of the plumbing system from the water well pressure system. Ball valves provide a way to shut off the water supply to the house in the event of a component failure in the plumbing system. For more information on ball valves, check out our blog,

isolation of the plumbing system from the water well pressure system. Ball valves provide a way to shut off the water supply to the house in the event of a component failure in the plumbing system. For more information on ball valves, check out our blog,  A sediment filters job is to remove the sediment from your water. This protects from sediment entering any water treatment equipment like softeners or hot water heaters. Having no sediment in the water treatment equipment increase the efficiency and longevity of the equipment. To get more details regarding spin out filters and separators, check out our post,

A sediment filters job is to remove the sediment from your water. This protects from sediment entering any water treatment equipment like softeners or hot water heaters. Having no sediment in the water treatment equipment increase the efficiency and longevity of the equipment. To get more details regarding spin out filters and separators, check out our post,